You might have heard about scleral contact lenses if regular contacts haven’t worked for you or if you have an eye condition that makes vision correction challenging. Spectrum Eye Care often recommends these specialized lenses when traditional options fall short, especially for people with conditions that make contact lenses hard to fit. Scleral contact lenses […]

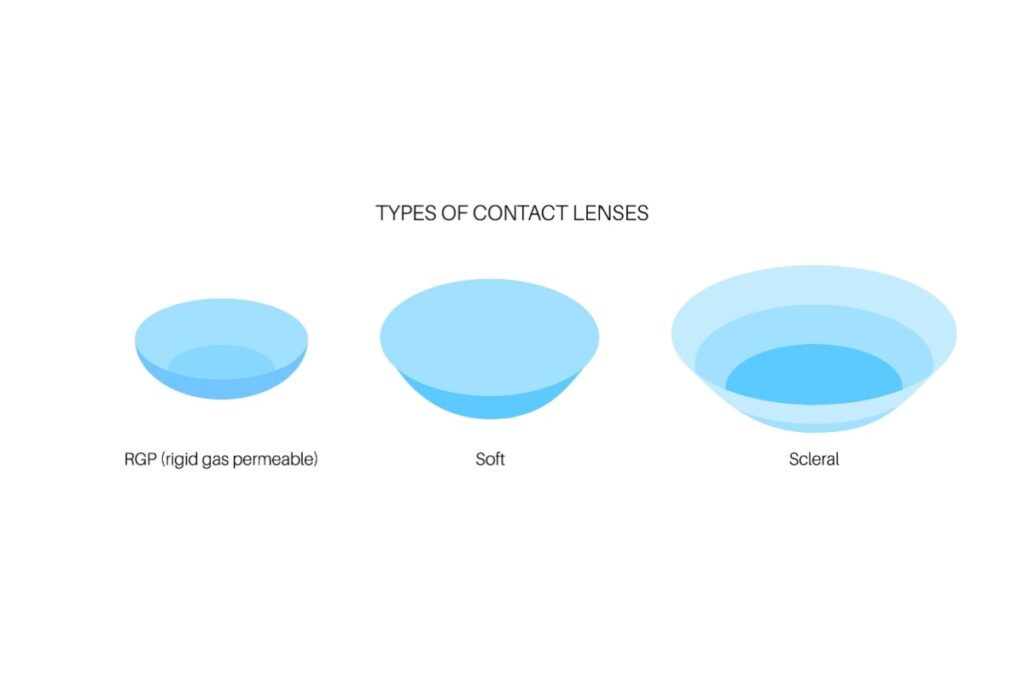

What are Scleral Contact Lenses?